3d Car Part Design Courses

Industrial 3D Scanner With Blue Light Technology

ATOS is metrology tested, aerospace certified accurate, and widely recognized as the preferred measuring tool.

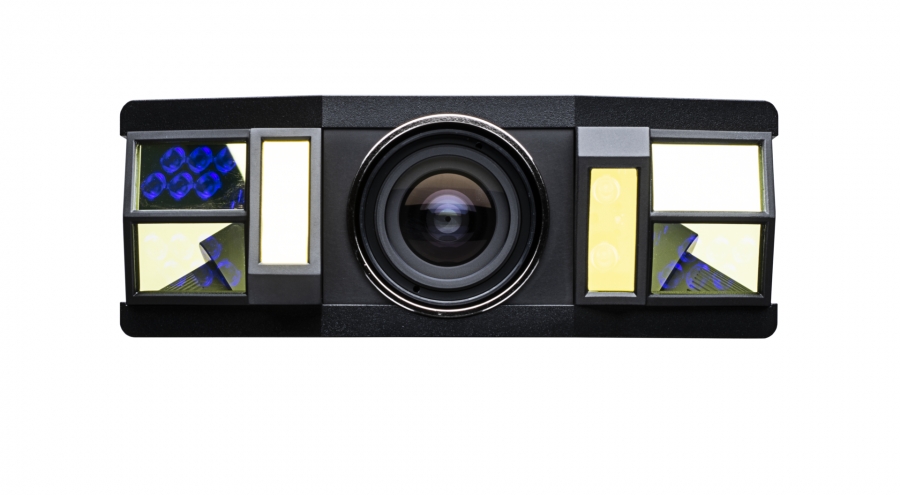

The ATOS series of high quality industrial structured blue light 3D scanners provide precision scans with detailed resolution at high speeds. ATOS is a type of a coordinate measuring machine CMM that utilizes optical non-contact technology to capture millions of accurate points in a single fast scan.

There are different names for this technology, such as, an optical measuring machine, optical 3D scanner, white light 3D scanner, blue light laser scanner, non-contact 3D scanner, etc. ATOS is engineered with advanced hardware and intelligent software for repeatable accurate measurements with flexibility and process reliability.

The ATOS generation of industrial 3D scanners is the most innovative optical measuring system for 3D coordinate measurement on the market. It is widely utilized in various industries, and can measure different object sizes, surface finishes, and shape complexities.

The science behind the technology.

In simplest terms, based on the principles of triangulation, the projector projects a fringe pattern across the part's surface and as the patterns rapidly shift during each scan, the two cameras capture the distortion to calculate the 3D coordinate measurements.

In a comparison to a traditional coordinate measuring machine (CMM), which takes a single measurement at each programmed point where the probe contacts the surface of the part, or an industrial 3D laser scanner that gathers measurement in strips or lines of data, ATOS is an optical non-contact measuring system that captures full-field scans of a volumetric area collecting millions of points per scan.

ATOS setup is minimal and each measurement can take less than 1 second. It does not require specialized programming skills or highly accurate fixtures. ATOS discovers discreet problematic areas that would have been undetected by traditional measurement methods by quickly scanning the entire object (part, mold, tool, die, etc.) in an accurate and dense point cloud.

This digital 3D blue print of the object's geometry is then compared to CAD with a 3D inspection color map displaying a spectrum of colors that signify areas in and/or out of tolerance.

As the saying goes, "A picture is worth 1,000 words." The 3D color map takes the uncertainty away so the optimal corrective action can be applied eliminating iterations and saving an enormous amount of costs and time that were once being spent on rework.

-

- Highly accurate traceable 3D measurements

-

- Detailed high resolution scans

-

- Quick data collection

-

- Advanced parametric inspection functionality

-

- Complete metrology solution for dimensional analysis (GD&T, trend analysis, industry specific inspection functionality, and much more…)

-

- Comprehensive reporting

Developed for industrial use, the ATOS 5 delivers high-precision data in a short measuring time even under harsh conditions. The full-field 3D measuring data allows comprehensive process and quality control, visualizing hidden errors and thus speeding up production processes. The right combination of hardware and software allows for safe integration of…

Engineered specially for the Industrial Gas Turbine Industry whether aerospace or ground powered applications providing accurate measurements for airfoil inspection. The ATOS 5 Airfoil delivers high-precision data in a short measuring time even under harsh conditions. The full-field 3D measuring data allows comprehensive process and quality control, visualizing hidden errors…

The ATOS 5X uses an integrated Laser Light Compressor to generate ultra-bright light, which allows for measuring areas of up to 1000mm while keeping exposure times extremely short—acquisition time is as low as 0.2 seconds per scan. This scanner was designed with automotive car body inspection in mind.

The ATOS Q is a powerful compact 3D scanner that acquires high-definition three-dimensional scans with high precision of various objects ranging from small to medium-sized parts across diverse industries. It features interchangeable measuring lenses for flexibility and a modern sleek design for portability.

The ATOS Capsule is an optical precision measuring machine (OPMM) for full-field 3D scanning of part geometries for dimensional inspection and/or reverse engineering applications. The fringe projection system of the ATOS series is used for quality assurance of small to medium-sized parts and excels by its high precision for fine…

The ATOS Compact Scan provides accurate scans with detailed versatile resolution at high speeds. This modern portable 3D scanner is engineered with high-quality components and ensures ultimate adaptability for various applications, part sizes, and environments, (especially in narrow and confined areas). It is a type of coordinate measuring machine (CMM)…

The GOM CT scanner enables the inspection of complex parts based on volumes. All surfaces—even internal structures—can, for example, be used for shape and dimension analyses or nominal-actual comparisons. The CT scanner is ideal for users who need to scan parts with complex internal structures that cannot be seen by…

The ATOS Plus intuitively integrates photogrammetry with the ATOS Triple Scan or ATOS Core 3D scanner to further advance automation, dimensional inspection analysis, verification, and process safety with a touch of a button. This dynamic combination enhances measurement accuracy, repeatability, and eliminates the need for costly precise fixtures.

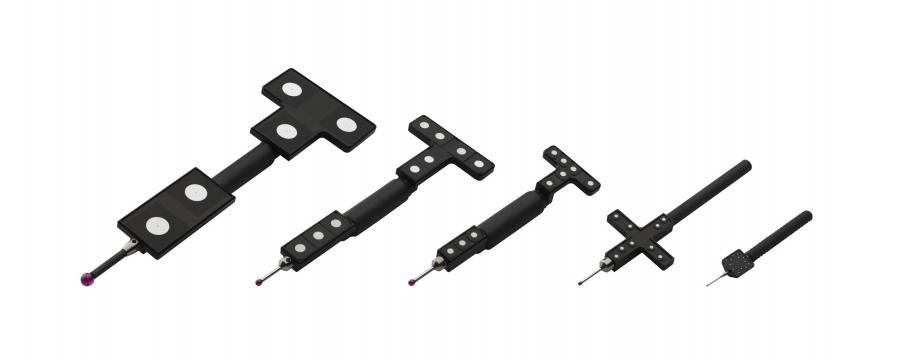

The GOM Touch Probe is an ATOS add-on option that enables 3D discrete point measurements in conjunction with ATOS full-field measurements for direct comparison to CAD for difficult to access areas, hidden cavities, discreet points and primitives. Touch probe data can also be utilized for online data alignment. For non-standard…

© Copyright 2021. Capture 3D, Inc. All Rights Reserved.

3d Car Part Design Courses

Source: https://www.capture3d.com/3d-metrology-solutions/3d-scanners

Posted by: powelltheretion.blogspot.com

0 Response to "3d Car Part Design Courses"

Post a Comment